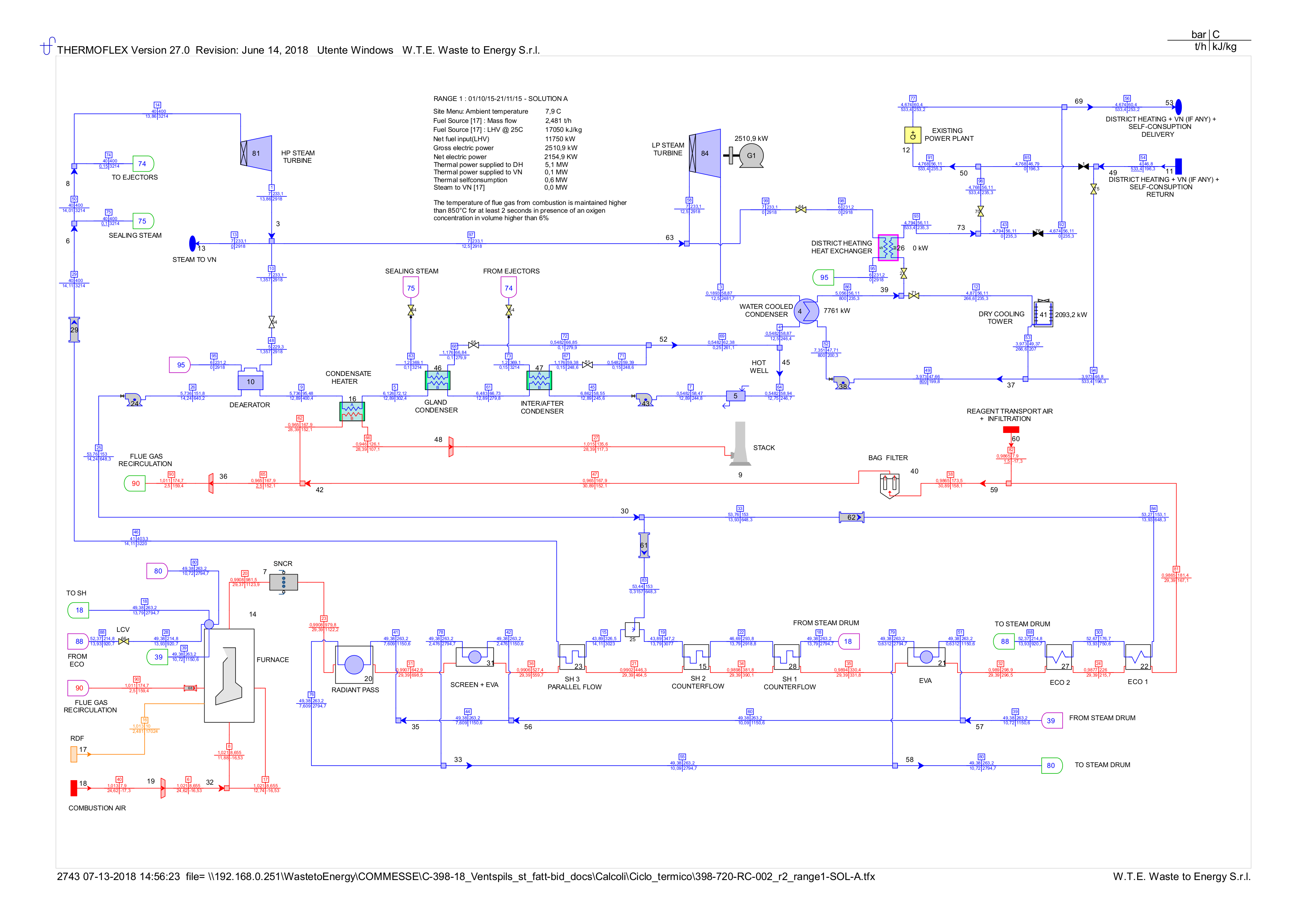

Thermal Cycles

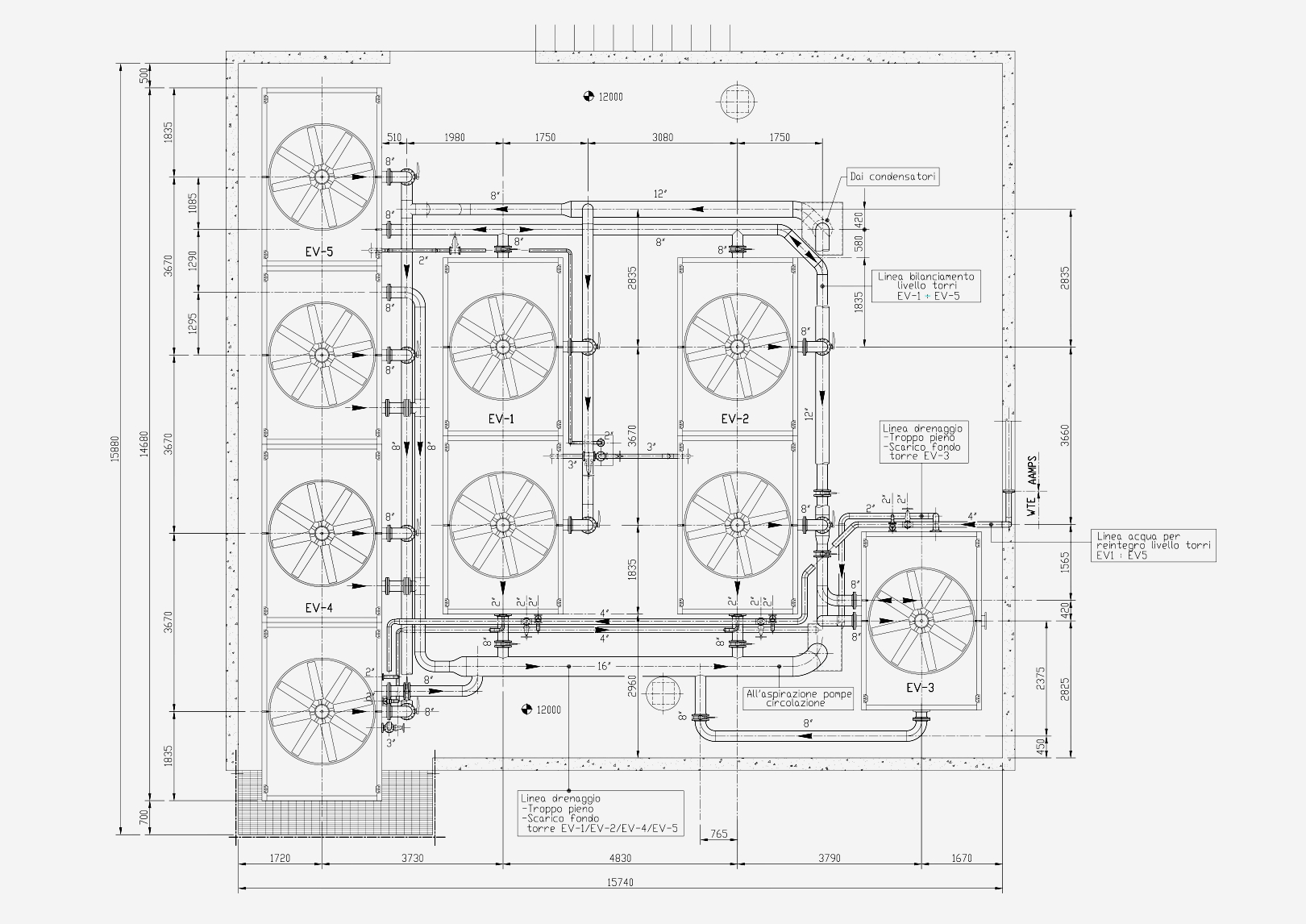

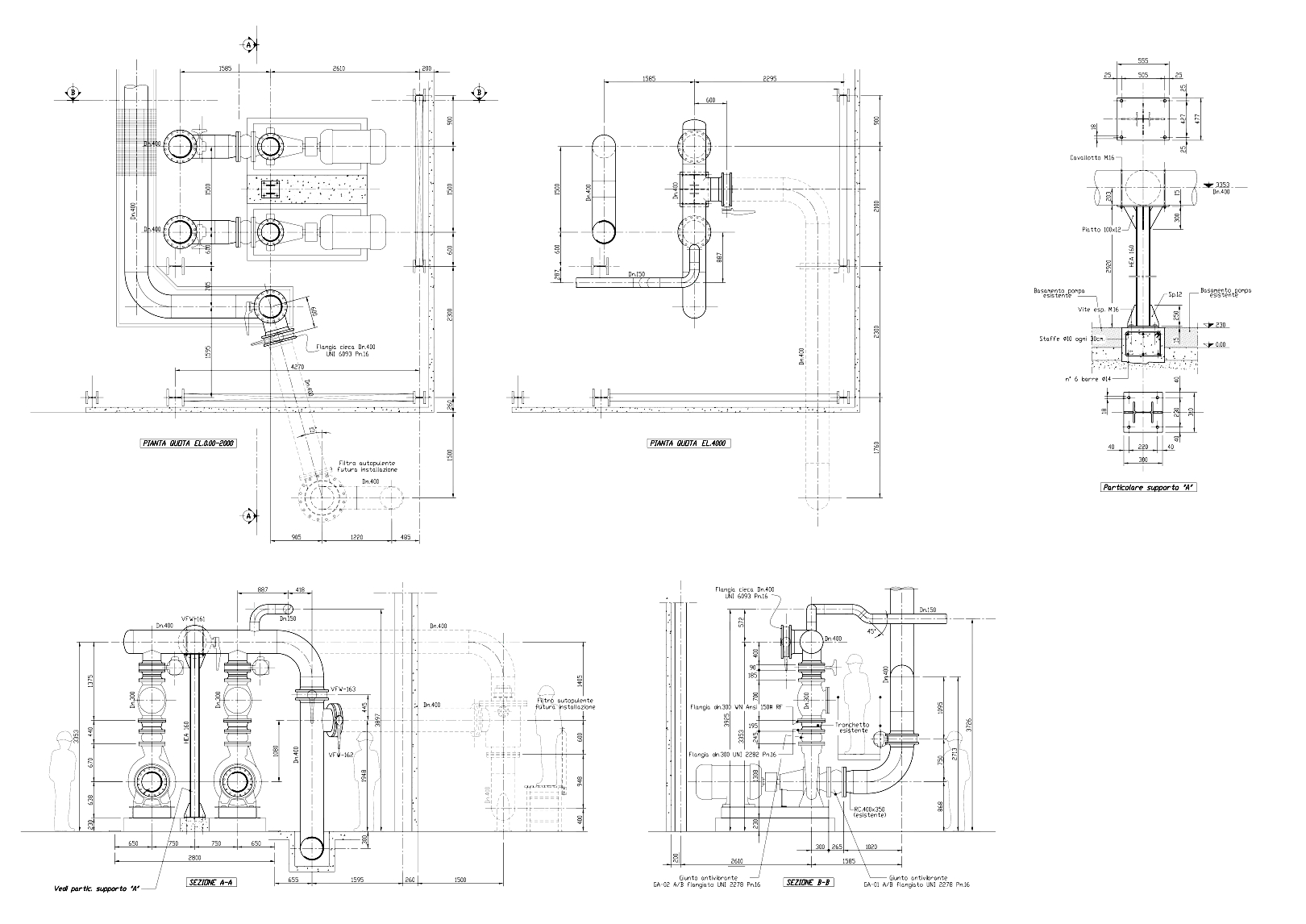

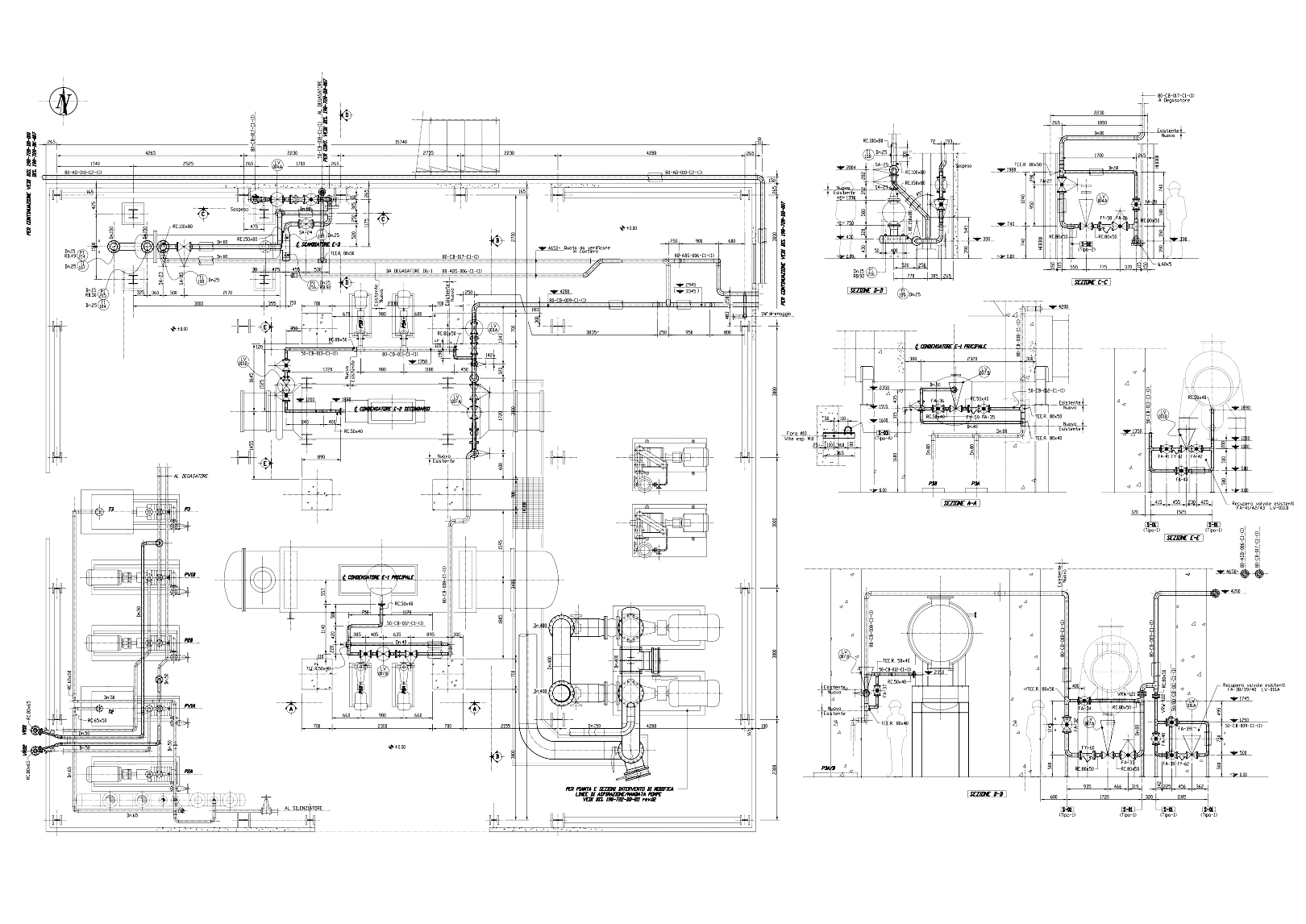

WTE can engineer and install thermal cycles for:

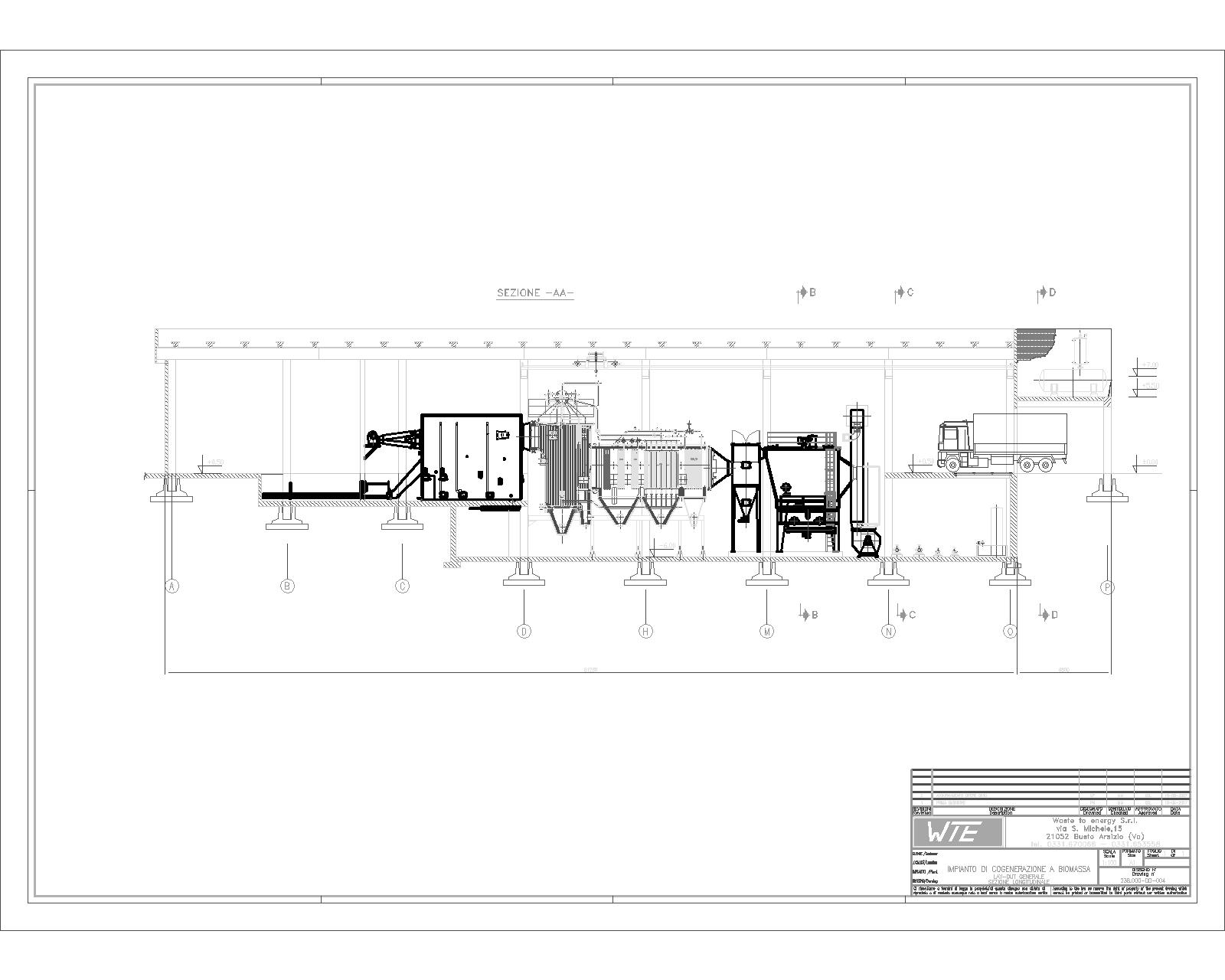

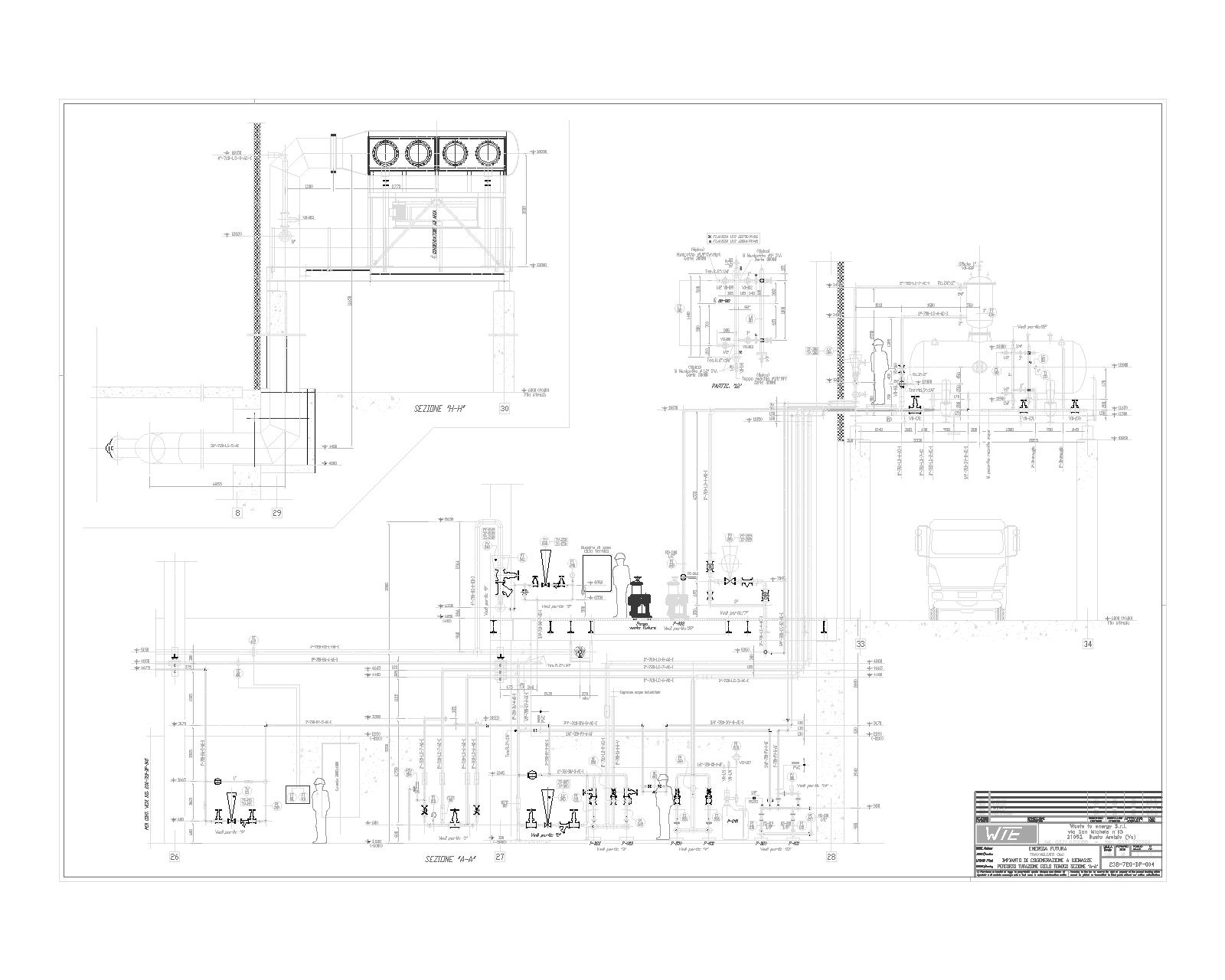

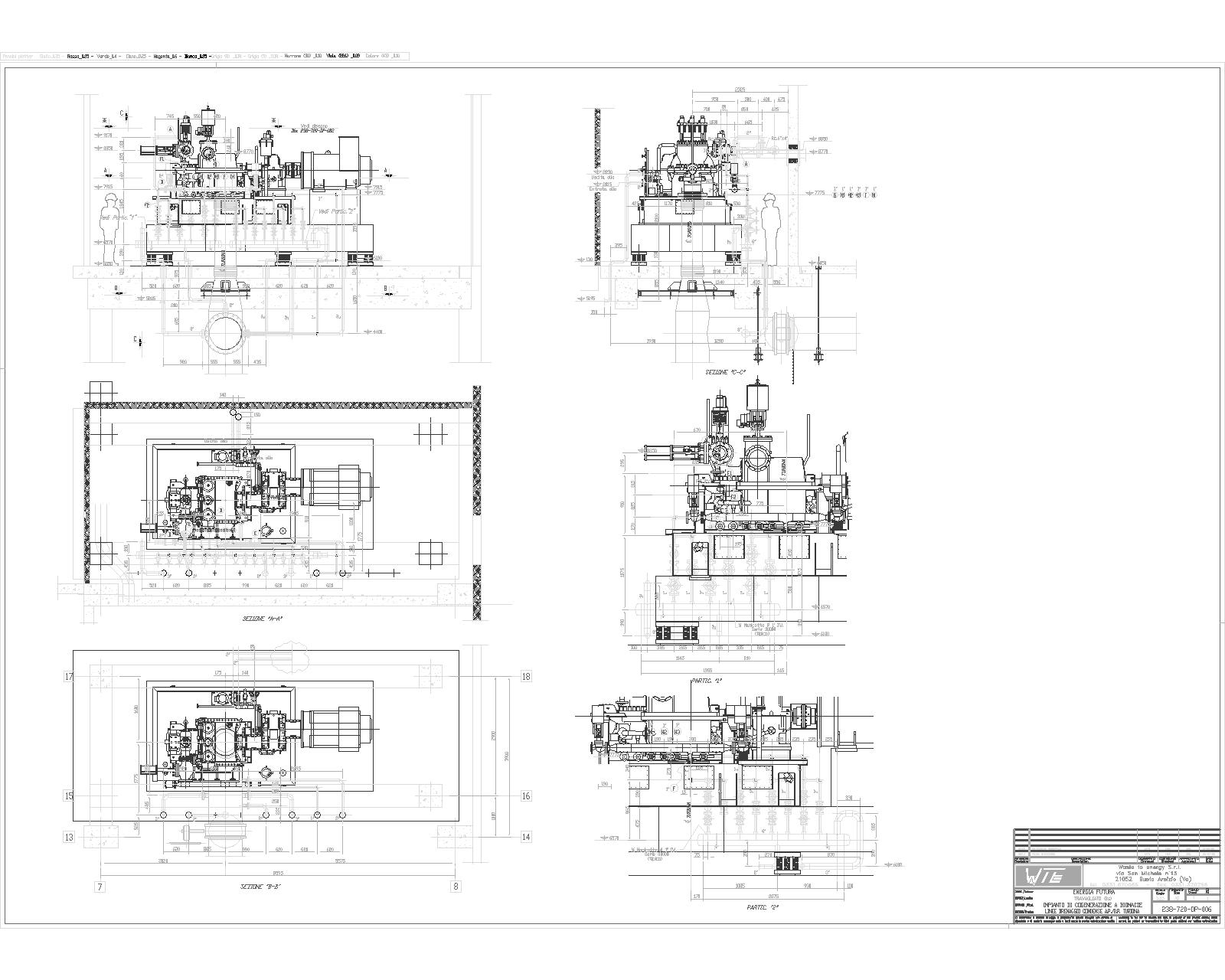

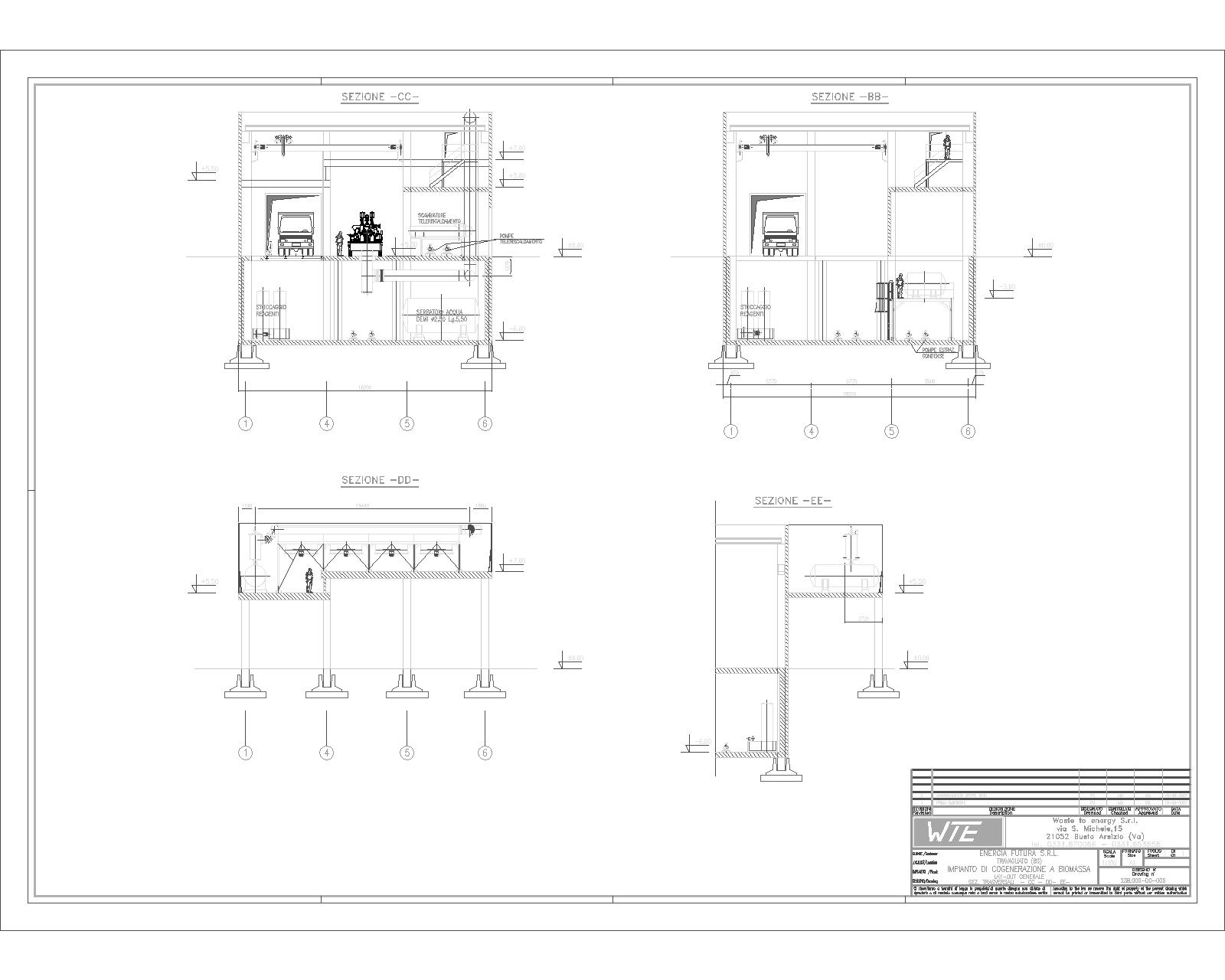

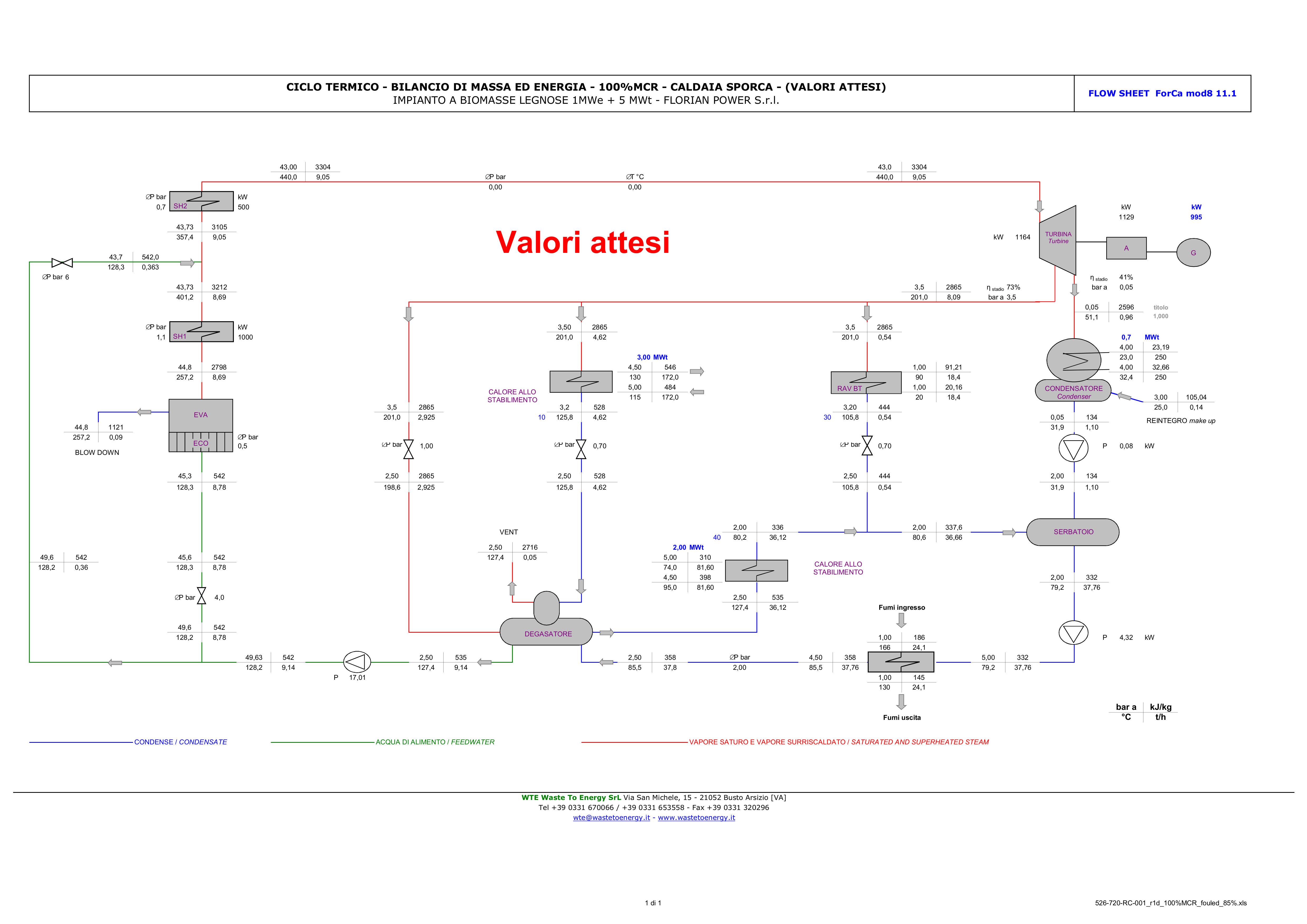

- waste to energy or biomass plants

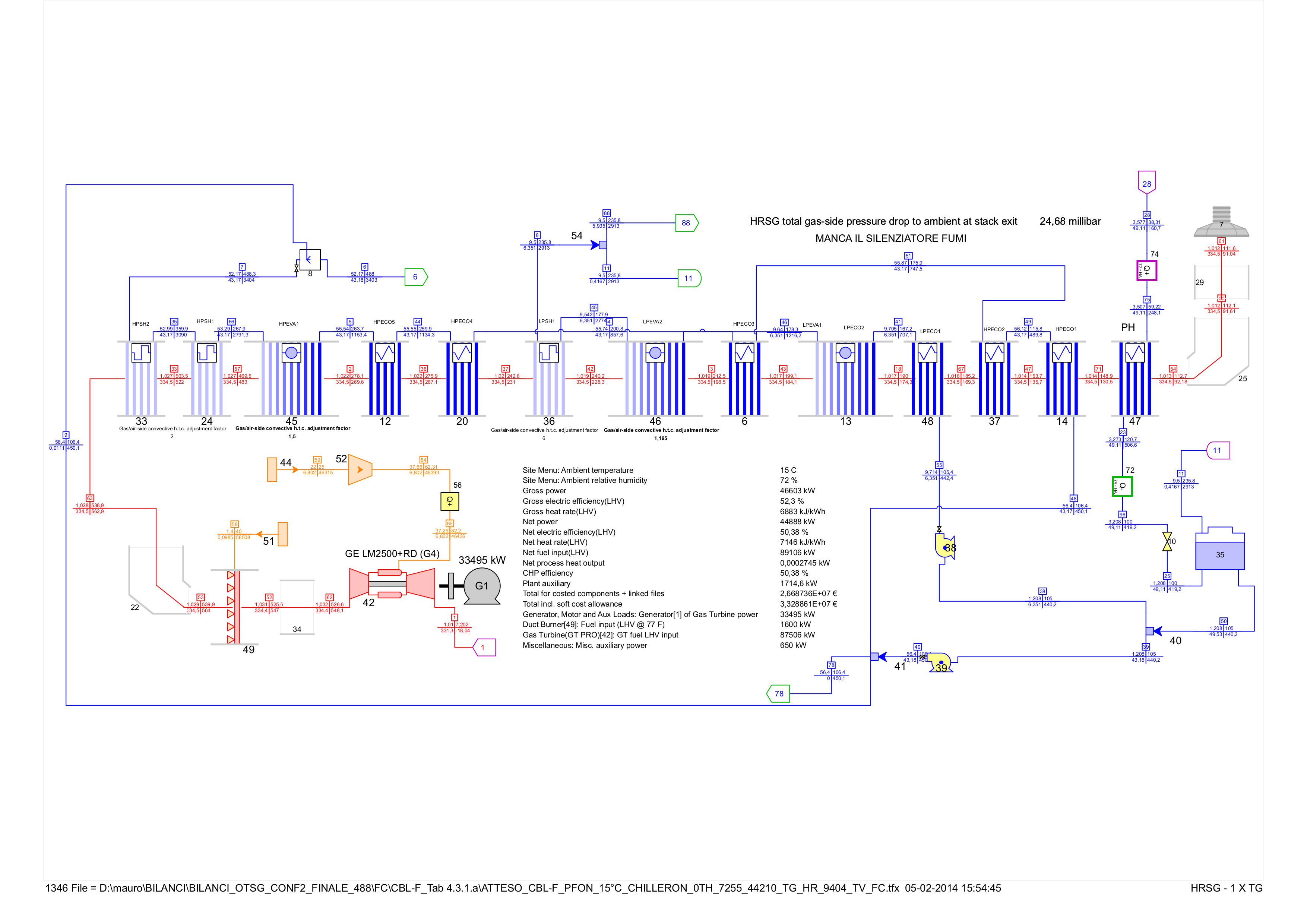

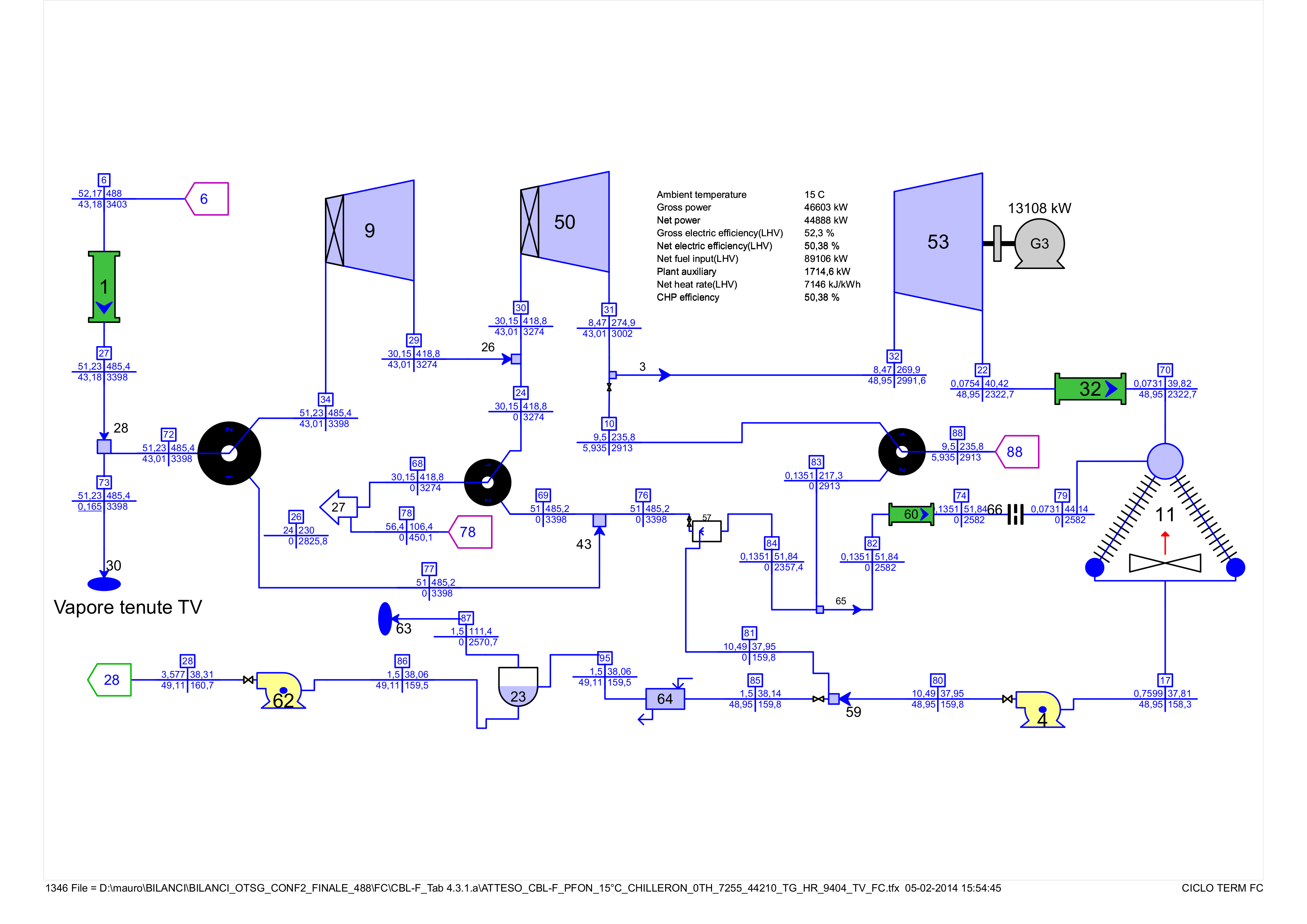

- Combined Cycle Power Plants, installing gas turbines (topping cycle) or steam turbines (bottoming cycle)

- waste heat recovery from generic industrial process.

Depending on the application thermal cycles can use as vector fluid steam as well as diathermic oil or other organic fluids

Our firm has a long experience in the design of thermal cycles of new waste-to-energy and biomass plants, and in the revamping of existing ones.

These cycles have some distinctive characteristics: above all, they must be designed considering that the operativity of the furnace/boiler and of the flue gas cleaning system is prioritary.

This means that in case of a “black out” the thermal cycle must have the capability to generate electric power satisfying the needs for self-consumption.

In an opposite situation, the thermal cycle must operate even with the turbine in idle, to ensure the continuity of waste disposal

We have developed proprietary models, to optimize the performances of thermal cycles through (among other things).

- designing multiple stages regenerative cycles, extracting steam from turbine at different pressures

- preheating of Combustion air

- preheating of condensate, using the sensible heat of combustion gas sent to the stack

- supercooling of fumes, to recover their sensible heat whIle sending them to stack

- installing, whenever possible, inverters to control the motors

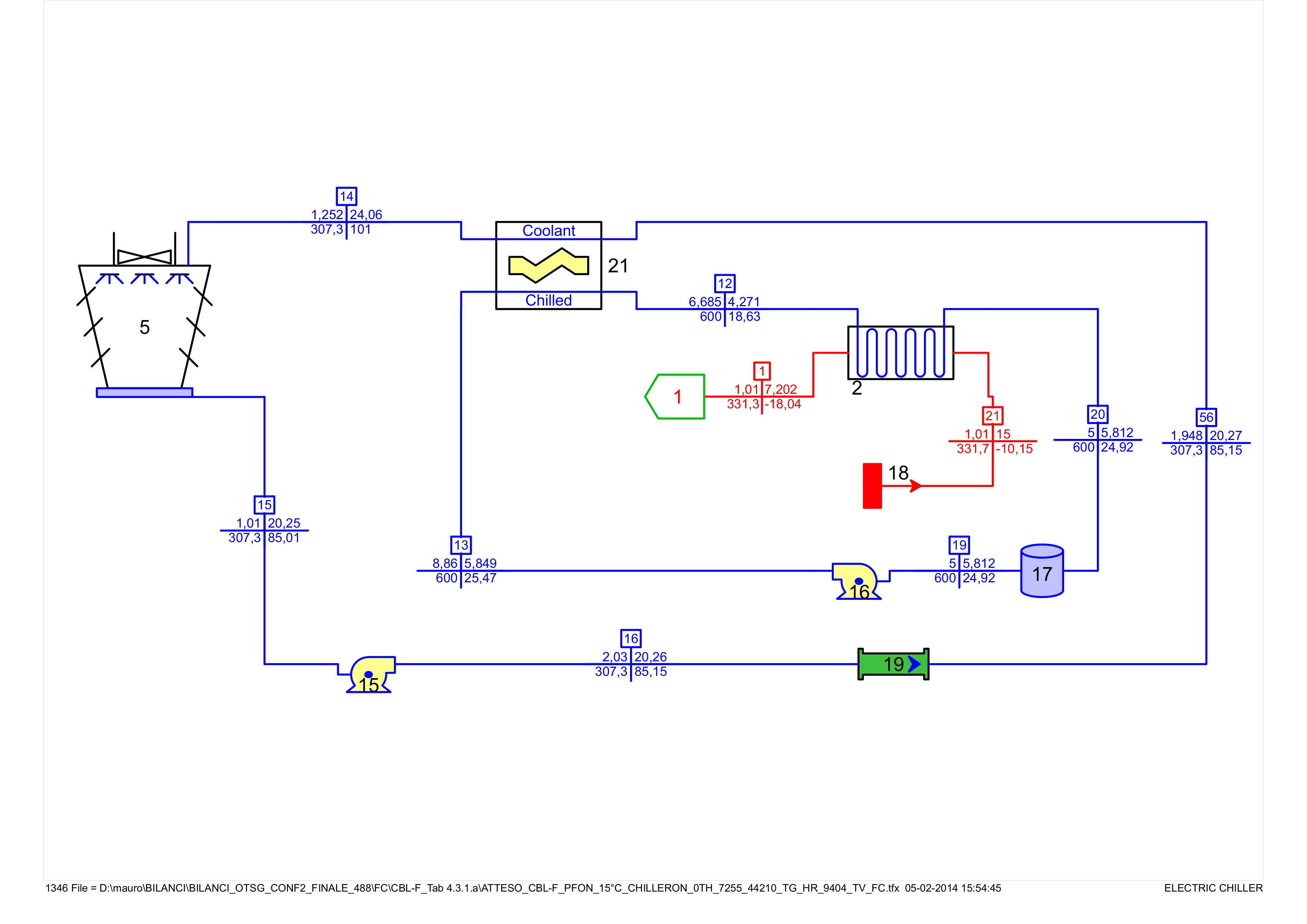

- engineering cogeneration (combines heat and power) or trigeneration (combined heat power cooling) systems

- developing an entropic analysis for an higher optimization of the thermal cycle

Slideshow

Highlights

Tell us about your next project

We love facing new challenges, discussing new ideas and envisaging new projects.

Feel free to contact us: we will be glad to exchange opinions, and to figure out how we can be of further help.